Get A Quote Now!

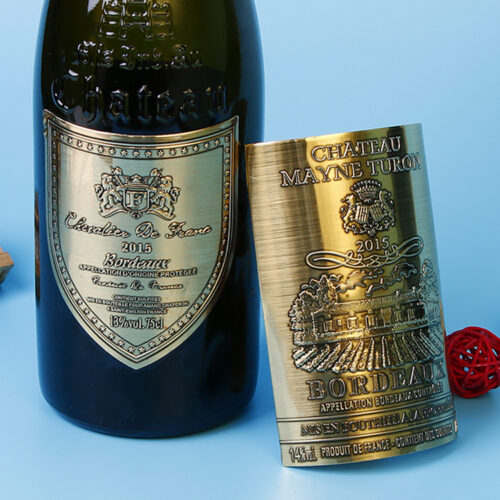

Producing custom metal wine labels offers many benefits, but it also comes with challenges. Understanding these hurdles and how to address them will help you get the best results for your brand.

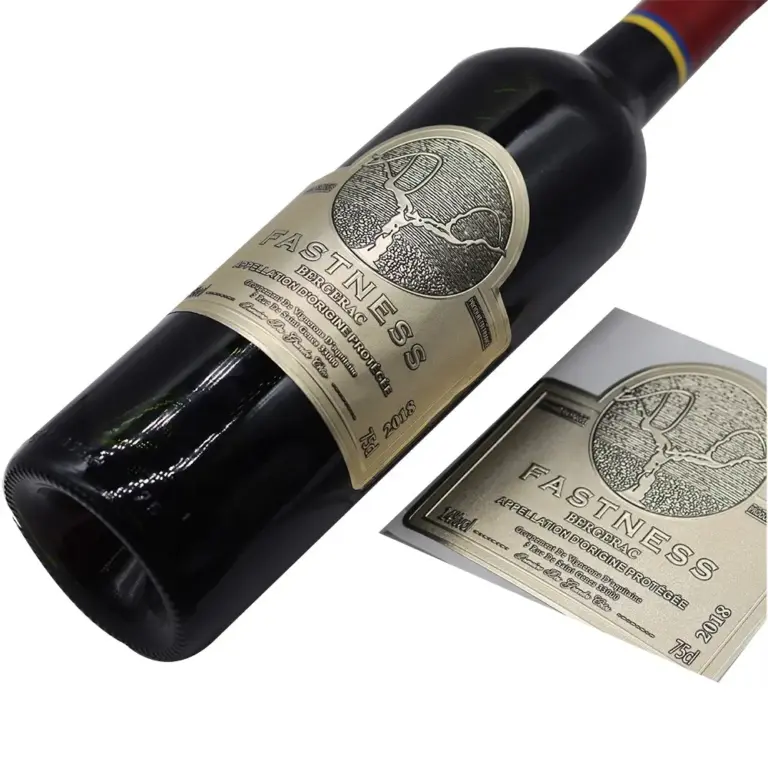

1. Adhesion Issues on Curved Bottles

Metal labels are rigid and heavier than paper, which can cause peeling or lifting on curved or textured glass surfaces.

Solution: Use specially formulated adhesives designed for glass and curved surfaces, and ensure bottles are clean and dry before application.

2. Design Complexity and Tooling Costs

Intricate designs with fine details can increase tooling costs and production time.

Solution: Work with experienced manufacturers who can advise on design feasibility and optimize artwork for cost-effective production.

3. Surface Finishing Variability

Achieving consistent finishes like brushing, plating, or painting can be challenging.

Solution: Request samples and prototypes to verify finishes before full production and choose reputable suppliers with quality controls.

4. Longer Lead Times Compared to Paper Labels

Metal labels require tooling, molding, and specialized finishing, leading to longer turnaround times.

Solution: Plan your production schedule in advance and communicate timelines clearly with your supplier.

5. Cost Considerations

Metal labels are generally more expensive than traditional paper labels, impacting budget.

Solution: Balance design complexity and materials with budget goals; consider metal labels for premium lines while using paper for standard products.

Conclusion

By anticipating and addressing these challenges, you can enjoy the benefits of metal wine labels while minimizing risks and delays.

Need help with your metal label project?

Contact MetalWineLabels.com for expert advice and support.

📩 Contact us

📦 Request free samples