Get A Quote Now!

Before placing your first order for custom metal wine labels, it’s essential to understand the practical side—MOQ (Minimum Order Quantity), lead times, and overall cost. These three factors determine your production schedule, budget, and even your label design options.

1. What Is the Minimum Order Quantity (MOQ)?

MOQ refers to the smallest number of units a manufacturer is willing to produce per order. For custom metal wine labels, this typically ranges from:

-

500–1,000 pieces for standard designs.

-

1,000+ pieces for complex or multi-process labels (e.g., embossed + color printed).

-

Some premium factories may offer lower MOQs for first-time clients or sample runs.

Why MOQs Exist: Creating molds, tools, and setups for metal labels involves fixed costs. Higher quantities help distribute that cost more efficiently.

2. What Is the Typical Lead Time?

The lead time refers to the time from order confirmation to delivery. For metal wine labels, this varies depending on complexity:

| Stage | Time Estimate |

|---|---|

| Artwork + Mockup | 2–3 business days |

| Tooling & Mold Creation | 5–7 business days |

| Production & Finishing | 10–15 business days |

| Quality Check & Packing | 2–3 business days |

| Shipping (by air/sea) | 3–15 days (location-based) |

Total Estimated Time: 3 to 4 weeks, but urgent orders can often be expedited upon request.

3. What Affects the Cost of Metal Wine Labels?

Metal label pricing depends on four main variables:

a. Material Type

-

Aluminum is the most affordable.

-

Zinc Alloy, Stainless Steel, and Tin cost more due to weight and processing difficulty.

b. Label Size & Thickness

-

Larger and thicker labels consume more raw material.

-

Labels over 1.5mm thick are typically used for luxury brands.

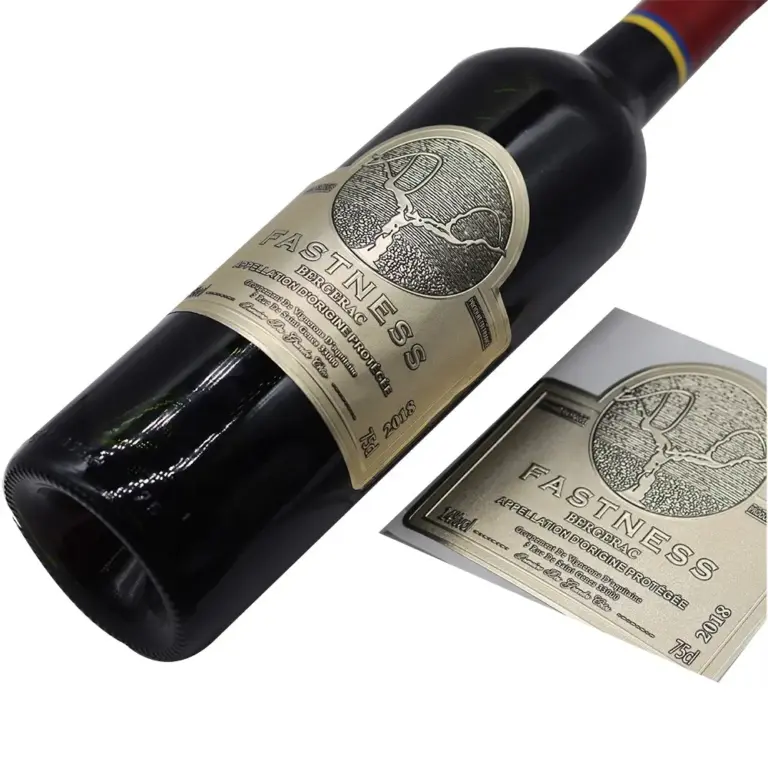

c. Process Complexity

-

Single-process labels (e.g. etching only) are cheaper.

-

Multi-process labels (e.g. embossing + color UV print + antique finish) increase cost.

d. Quantity Ordered

-

Unit cost decreases significantly with higher volumes.

-

Economies of scale begin to show after 1,000 pieces.

4. Are There Any Hidden Costs?

Ask upfront about:

-

Mold/tooling charges (often a one-time fee for custom shapes).

-

Setup charges for each finishing technique.

-

Shipping fees (especially for international deliveries).

5. Tips to Optimize Your Budget

-

Start with a standard shape to avoid tooling charges.

-

Use aluminum for cost-effective bulk runs.

-

Combine processes smartly—for example, emboss + brushed instead of emboss + print + plating.

Final Thoughts

Understanding MOQ, lead time, and pricing helps you plan confidently, avoid surprises, and choose the right combination of customization and budget.

Ready to start your custom metal label order?

📩 Contact MetalWineLabels.com

📦 Request a free sample or custom quote