Get A Quote Now!

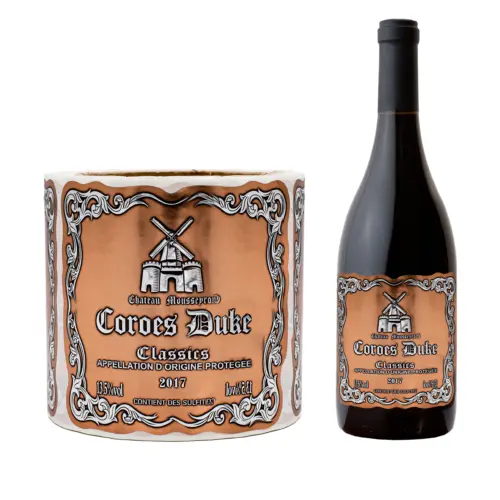

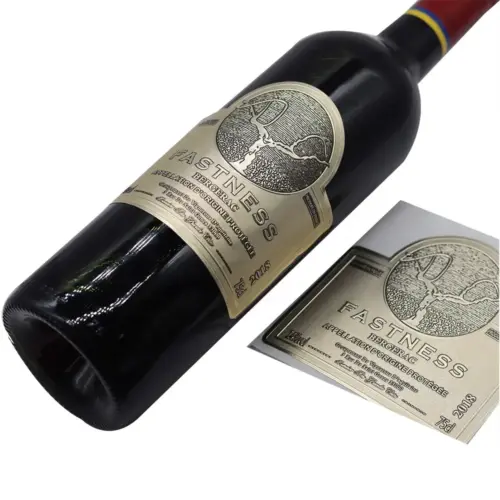

Designing a custom metal wine label isn’t just about the material or finish—it’s also about getting the right size and shape to fit your bottle, elevate your branding, and ensure perfect application. Here’s a practical guide to help you make the best choice for your label layout.

1. Consider the Bottle Type First

Different wine bottles have different surface contours. The most common bottle styles include:

-

Bordeaux (tall shoulders, straight sides)

-

Burgundy (gentle sloping shoulders)

-

Champagne (thicker walls, larger body)

-

Specialty bottles (flat sides, curves, or decorative shapes)

Tip: Measure the label area after accounting for any taper or curve, especially for wrap-around or oversized labels.

2. Common Label Sizes (Reference)

| Label Type | Typical Dimensions | Best For |

|---|---|---|

| Main Body Label | 60mm x 90mm ~ 80mm x 120mm | Standard front branding |

| Neck Label | 30mm x 50mm | Logo or emblem |

| Medallion/Badge | Ø30mm – Ø50mm (circular) | Premium brand mark |

| Wrap-around Label | Custom, based on bottle size | Limited editions or sets |

Need a unique size? Most metal label makers (including us) support fully custom die-cut shapes.

3. Choosing the Right Shape

The shape of your label is where branding really comes alive:

-

Rectangular: Clean and versatile. Works well with most fonts and layouts.

-

Oval: Classic elegance. Great for traditional or vintage labels.

-

Circular/Badge: Iconic, often used for crests or neck branding.

-

Die-Cut Custom Shapes: Fully tailored outlines—shields, grapes, leaves, logos—anything that enhances your identity.

Pro tip: Avoid overly sharp corners on thick metal labels—they can feel uncomfortable or lift over time.

4. Match Label Size to Brand Messaging

-

Larger Labels command more attention, ideal for premium and gift wines.

-

Compact Labels feel artisanal, minimalist, or boutique.

-

Multi-label Sets (e.g., body + neck + badge) add luxury appeal and design flexibility.

5. Technical Considerations

-

Adhesion Area: Ensure enough flat surface area for full adhesive contact.

-

Bottle Taper: On curved bottles, too wide a label may wrinkle or not sit flush.

-

Weight of the Label: Heavier metals (like zinc alloy) may require stronger adhesive or a smaller footprint.

Conclusion

Your label’s size and shape are more than just design choices—they influence usability, shelf presence, and consumer perception. The right proportions ensure a snug fit and a standout look.

Need help with sizing or custom shapes?

📩 Contact us at MetalWineLabels.com

🖼️ Request a design consultation or sample kit