Get A Quote Now!

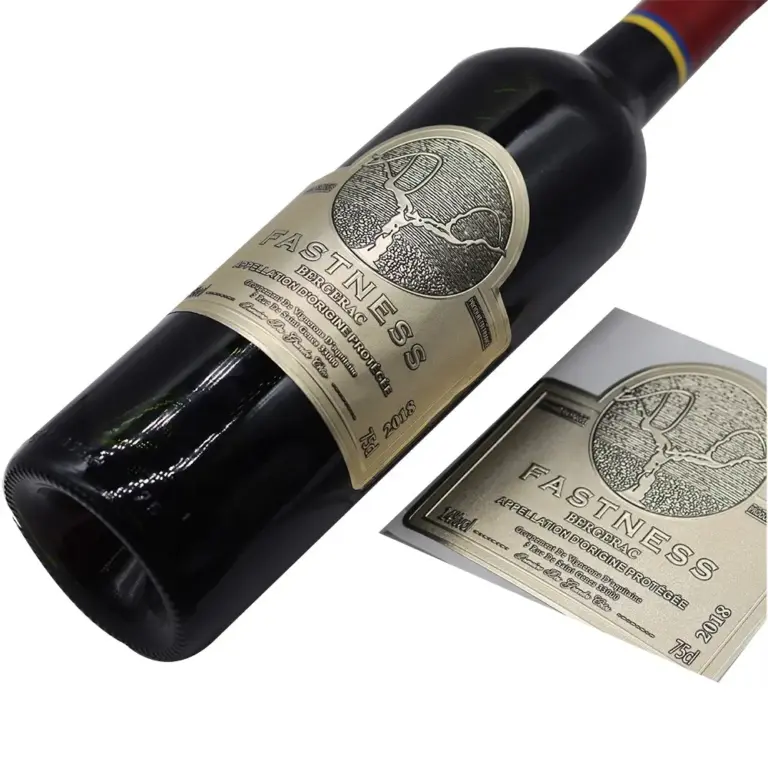

If you’re considering elevating your wine packaging with custom metal labels, understanding the production process is key. Not only does it help you make informed decisions, but it also gives you insight into lead times, costs, and customization options.

Here’s a complete step-by-step breakdown of how premium metal wine labels are made — from concept to final shipment.

Step 1: Design Submission & Digital Proofing

Everything starts with your artwork. You submit your:

-

Brand logo

-

Label shape (rectangle, oval, custom die-cut)

-

Preferred size and color

-

Text and layout

Our team converts this into a vector format suitable for engraving or embossing. You’ll receive a digital 3D mockup showing how your label will look on a bottle.

✅ Tip: Want to see how different finishes look on your label? Request multiple mockups — matte, antique, brushed, or glossy.

Step 2: Material Selection

Choose from premium materials such as:

-

Aluminum (lightweight, cost-effective)

-

Zinc Alloy (luxury, deep embossing)

-

Tin (soft, classic, vintage)

-

Stainless Steel (sleek, modern)

Each metal offers different benefits in terms of texture, weight, and cost. Your selection affects both the visual effect and production method.

Step 3: Tooling & Mold Creation

Once the design and material are confirmed, we create precision molds or stamping dies using CNC machining.

-

For embossed labels, a die-and-counter-die set is made.

-

For etched or engraved labels, a laser template is prepared.

-

For die-cast zinc alloy, a custom 3D mold is produced.

This tooling process ensures that each label is consistently shaped and dimensionally accurate.

Step 4: Forming & Shaping

Depending on the technique, labels are shaped using:

-

Stamping/pressing (for aluminum and tin)

-

Die-casting (for zinc alloy)

-

Laser cutting (for complex outlines)

Edges are trimmed, curves are refined, and mounting holes (if needed) are pre-cut. For intricate logos, this is where the real craftsmanship begins.

Step 5: Surface Finishing

Surface treatment dramatically changes how your label feels and looks. Options include:

-

Brushed – satin texture, modern look

-

Mirror polished – glossy, reflective

-

Antique plated – vintage character

-

Matte – understated luxury

-

Dual finish – contrast gloss + matte areas

Additional techniques like anodizing, sandblasting, or electroplating may be applied depending on the design.

Step 6: Printing or Engraving

Next, we add your design details through various methods:

-

UV printing – Full-color graphics with fast turnaround

-

Screen printing – Spot colors with durable ink layers

-

Laser engraving – Permanent, precise, no fading

-

Etching – Chemical or laser etching for subtle depth and texture

This is where brand names, grape varietals, vintage years, and QR codes are added.

Step 7: Adhesive Application or Backing Options

We finish the label with the right backing for your application:

-

3M adhesive – Strong and reliable for bottle application

-

Magnetic backing – Optional for collectible or reusable labels

-

Rivets or holes – For attaching to wooden boxes or gift packaging

📦 Labels are now ready for packaging — securely and professionally boxed to prevent bending, scratching, or moisture damage during transport.

Step 8: Final QC, Packaging & Delivery

Each label undergoes strict quality control:

-

Surface inspection for scratches or plating defects

-

Adhesion tests (for stickers)

-

Dimensional accuracy checks

After passing QC, your order is carefully packed and shipped via DHL, FedEx, or air freight, depending on urgency.

Total Lead Time

-

Sampling: 5–7 working days

-

Bulk Production: 12–20 days depending on order size & process complexity

-

Shipping: 3–7 days globally via express air

Why This Process Matters

Understanding the process helps:

-

Minimize miscommunication during ordering

-

Clarify what impacts cost (e.g. die-casting vs. stamping)

-

Choose the right material + finish for your brand identity

-

Speed up sampling and approvals

Let’s Bring Your Label to Life

At MetalWineLabels.com, we specialize in turning winery stories into tactile, unforgettable packaging. Whether you need 500 or 50,000 pieces, we bring craftsmanship, speed, and global shipping under one roof.

📩 Request a quote or submit your design

📦 Order a free sample kit and see the difference firsthand

Your bottle deserves more than paper — it deserves metal.